NICHOLAS HEATH UNPACKS THE FATE OF AVIATION FUEL AND ALTERNATIVES TO TRADITIONAL, CARBON-HEAVY FUELS.

One of the biggest threats to our future enjoyment of light aviation is availability of fuel. There’s a perfect storm of forces brewing that can potentially threaten future fuel supplies for aviation. The most obvious is the imminent removal of 100LL fuel. The US is moving to replace 100LL with an unleaded alternative by 2030. In 2022, the US approved G100UL. I know for a lot of you that won’t matter; Avgas can be replaced with Mogas or G100UL. But it isn’t that simple for all. CASA has advised that you can only use a fuel if it is specified for that engine. And here’s the rub; engines have a life in decades. So much of the changing technology won’t even be on the horizon when an engine is developed and sold. Let’s not even get into the fact that so many aviation engines date their origins back to the postwar period, back when lead was a good thing. Now we know better and leaded fuel is on the naughty list. If this was the only cloud on our horizon, it would be smooth flying. But it’s not. Whether it’s unleaded or not, aviation fuel has a large carbon footprint and even those of us living in a cave appreciate that the change is on for carbon heavy fuels.

In Australia, the target is net zero carbon emissions by By 2030, we are meant to have reduced it by 43%. Currently, we have achieved less than 25%. You can imagine that aviation fuel will come into the sights of politicians very soon. For a last kick in the pants, there will come a point at which supplying gasolinestyle aviation fuels may not be viable. Most commercial aviation uses kerosene-based jet fuels. That leaves recreational and smaller commercial operators on Avgas as a minority. At the very least, you can expect gasoline-based fuels to dramatically increase in price. Isn’t that great? In short, we need to find an alternative to traditional, carbon-heavy fuels and we need it sooner rather than later.

So, where to from here? Well, there’s some contenders on the horizon. For cars it appears that electric vehicles will be the path forward. But cars aren’t as weight-sensitive as aircraft, so that heavy battery is the stumbling block. An electric car has typically between half and three quarters of a tonne of battery in it. Sure, there’s some weight savings in the engine. But that might be 50 kilograms. There are electric aircraft flying right now, but to do that they compromise on range. The Alpha Electro by Pipistrel is claimed to be the world’s first certified electric aircraft and has an endurance of 50 minutes. That might be suitable for training flights, and short hops, but not much more. Sure, as battery technology improves, we will see that improve. But under the current chemistry we will hit a point where efficiencies are approaching a maximum. At that maximum, we still won’t see capacity for multiple hours of flight. Short of a paradigm shift in battery technology – and whoever comes up with it will be the richest person on earth – we won’t see electric aircraft replacing combustion aircraft anytime soon. And that still won’t help the existing fleet.

Another much-vaunted technology is hydrogen. It’s a combustion process like gasoline. It’s green because you make hydrogen by splitting water and when you burn it, it goes back to being water. If you can make that with green energy like wind or solar (and yes, I know there is a carbon cost to those) then you have a notionally green or at least carbon-reduced fuel. Hydrogen when liquified has three times the energy density of Jet A-1 fuel. Hydrogen is indeed a potential wonder fuel but it has one major stumbling block: storage. To compress and liquify hydrogen you need to reduce its temperature to -253 degrees centigrade. That is cold. Ironically, to compress it they use something that resembles a jet engine. Once compressed it needs to be stored which requires high pressure – say up to 800 bar – and cryogenic insulation. Think a giant thermos with enough pressure in it that if it decompresses the explosion from that will leave a crater. But that will pale in to insignificance if it ignites and you will get something that looks a lot like a rocket exploding at launch. That’s probably not going to be a great outcome for aviation.

There is one other tricky way to store hydrogen – you get it to bond to a substance like a metal latticework with a huge surface area. The problem for aviation is again our old friend weight. Even if this methodology passes from the lab to application – and that’s not a guide – then we probably won’t see it used in planes. Ships, heavy tracks and similar vehicles might be the beneficiaries of hydrogen fuels this century. Once again, not much help to the existing fleet.

So where does that leave us? Well, right back where we started with liquid gasoline fuels. It’s easy to see why it’s hard to shift. We have a fleet of aircraft designed to use them. We have a delivery system designed around those fuels and much of our education and air law enshrines their use. But do internal combustion fuels have to be carbon producers? The answer is definitely maybe. One way to at least reduce the amount of carbon produced significantly is with so-called bio-fuels. That is fuel which has been blended with a fuel created from a source like vegetable oil and/or ethanol – both of which can be grown as crops. E10 pump fuel available across Australia has 10% ethanol. But at its best, for gasoline-based fuels, blended biofuels will only reduce a portion of the carbon footprint – not forgetting there is a carbon cost to producing them too. You can make something very close to diesel as a 100% biofuel with a combination of ethanol and oil which could be a substitute for Jet A-1. There’s a whole bunch of quality and preservation issues to overcome, but it’s possible. However, it still won’t help the gasoline-based fleet.

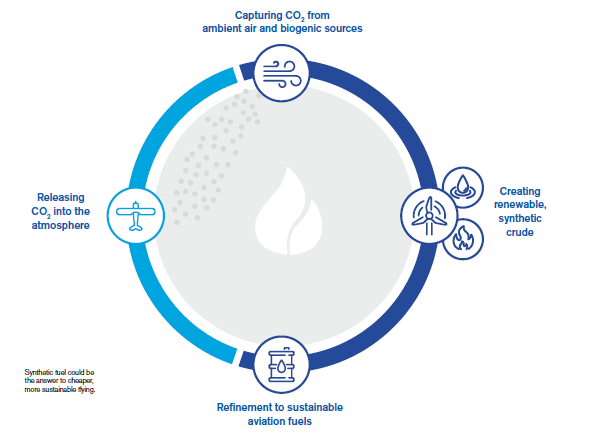

Back in WWII when fuel supplies were so critical that they were rationed, Australia started making synthetic fuels to address the fuel crisis brought on by the war. The process for making synthetic fuel had been developed by a German, Friedrich Bergius back in 1913. The process took coal as a feedstock and converted it in to fuel. Not surprisingly, it was Germany with limited fuel sources that was most advanced in synthetic fuel production, with aviation fuel being the top priority. That process used coal. Not great for a carbon reduction program. But it doesn’t have to be coal. Any carbon heavy feedstock could be used, including (drumroll please) carbon dioxide. You know, that thing that is killing the planet? Don’t get too excited though. It’s not like we aren’t going to burn the fuel eventually and turn it back in to carbon dioxide. The important thing is that it can be a closed carbon circuit.

Jump forward nearly 80 years and everything old is new again. Synthetic fuels are back as a hot topic. And yes, with the right amount of resources, money and willpower you can make an Avgas substitute that will work in our existing aircraft. Better still, it can – with suitable testing and approval – go straight into the existing fleet using the existing delivery system. You can even use synthetic valve lubricants and anti-knock additives that will replace the role of tetraethyl lead. The product will be a synthetic aviation gasoline, which they have called SynAvGas (how long was that meeting?) and it promises the solution we all hope for. But – and it’s a mighty big but – can it be done at a reasonable price? That’s the real question. In theory yes. Particularly if you are using cheap renewable energy to run the process and your feedstock is, say, hydrogen and carbon dioxide. The bi-product is oxygen. And who doesn’t love oxygen? That deals with the existing fleet, but what about moving forward? Annoyingly, it is far easier to make jet fuel substitute than gasoline – partly because it is a much less refined product and partly because it has a simplified chemistry. So, the best hope for Avgas based engines and ultimately Mogas based engines – because that stuff won’t be around forever either – is that synthetic fuels become both available and affordable. Secondly, given the ease with which synthetic jet fuel can be created and the dependance of commercial aviation on it, you can guarantee that there will be synthetic jet fuel available cheaper and sooner than synthetic Avgas – sorry SynAvGas. If I was a betting man and I was buying a new aircraft, I’d be looking for a diesel option that can run on JetA1/AvTur.