Earlier this year I took a friend up for his first flight. Moments short of home at Lethbridge, the tacho needle went flat. Whilst I was pretty sure it wasn’t the full emergency scenario, once back on the ground, some lessons would be learnt.

Some friends came down from Sydney mid-year, and as one of them is always keen to get in the cockpit, one day I took him for a coastal spin in the RV-6A. It’s a fun and robust plane and hadn’t let me down yet. On return, I noticed the ammeter was sitting a little left of centre than usual, but it flickers so much I was questioning my own recollection of its happy place. Seconds later, a circuit breaker popped, and I watched the tacho needle drop to 0 RPM. The aircraft and engine felt stable and I couldn’t identify any other issues, but it was time to land.

At this point, I couldn’t understand why the tacho would die on me, making it difficult to figure out how much of a problem I had on my hands – a loose wire, or something more sinister. The only instrument I’d ever lost was a trim indicator, but it returned again mid-flight.

My first reaction was to remove some things from my plate. I checked for an unlikely fire, ran all my downwind checks so I knew I was good to land, had my radio and transponder at the ready, and we were moments from home – always a comforting feeling.

On the ground, I ran through all the pre-flight and shutdown checks to try and identify anything wrong but found nothing else. The tacho twitched slightly if I opened or closed the circuit breaker, but that was it. At the time, I thought the tacho worked by generating a small current like the old ones do, however, a phone call to my LAME led me to understand this one draws from the battery. A power problem, eh?

That had me thinking battery, alternators, fuses/breakers or wiring in between. Now to narrow things down a bit.

The battery was comfortably firing up the plane. I noticed it seemed a bit more tired today, but I thought it was just a cold start. Nicholas Heath (Editor) had just returned from his big trip to the top of Australia and back… surely the plane was in good shape after having a good run? How naïve of me to think so.

I uninstalled the battery – my tester said it was OK, but something had to be wrong. I took it to a professional to test, who fitted up a giant resister and applied a load similar to the engine start-up. Fail. We then read the serial number on the battery to discover it was made in October 2010. How did this slip through the cracks? When was the last time you really checked the battery in your aircraft?

“Often we don’t think about it until the time comes that it stops working… but that can happen mid-flight.“

In theory, I could have flicked off electronics and ran the engine on the magnetos for plenty of time. It’s a naturally aspirated, air-cooled Lycoming 0-320, which means it doesn’t really have fuel injectors or other electronics that can fail. Nevertheless, I wasn’t in a rush to find out how far it’ll go on a dying battery.

Outside the cockpit, the battery sat at 12.4V. Next was to install and test again: we should see 12.3 to 12.4V in the cockpit, and as the engine turns over it should drop in voltage, recover and then sit at around 14.2 to 14.4V. Nope. The engine spun away and the power draw was evident, but was not recovering and very slowly depleting due to the avionics. I was using the Dynon EFIS for battery monitoring and a multi-meter for a second opinion. No issues with breakers and fuses. The battery was doing its job, but something was failing; the alternator.

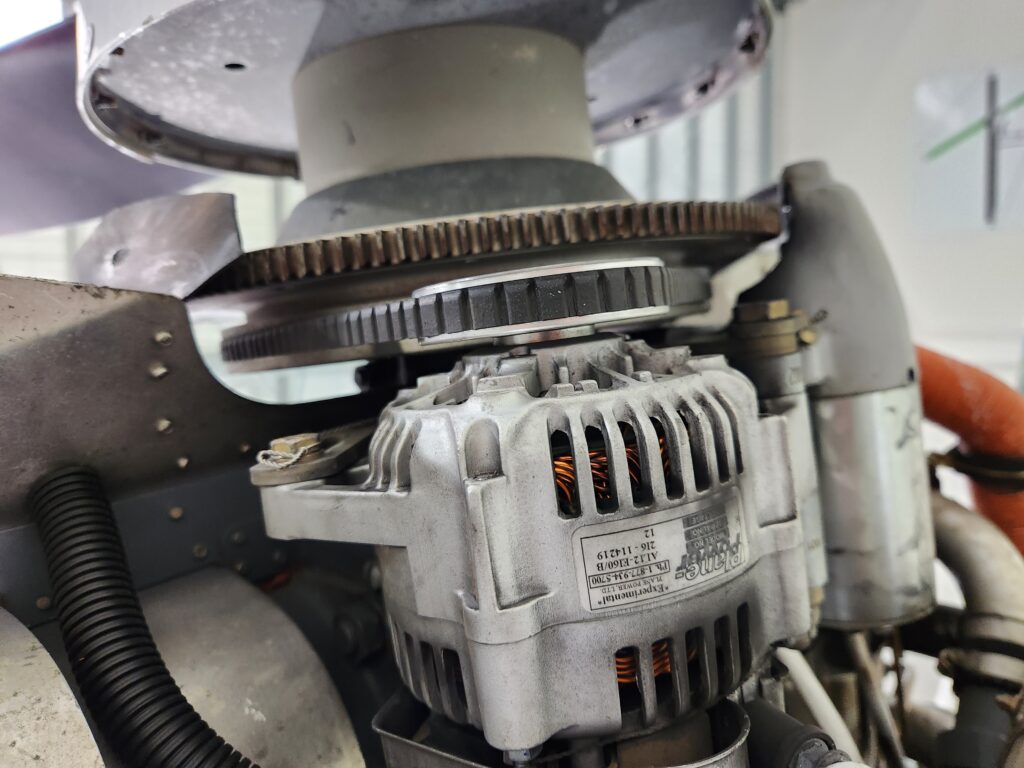

Secretly, we were hoping the alternator was fine. (A) It’s a more expensive part to fix, and (B) if you’ve ever pulled the cowls off an RV-6A, you’ll know that it’d be a much faster job to count the grains of sand on the beaches of Gippsland. So, after my brief tears, off came the cowls.

It was kind of refreshing to go whole-hog under the cowling, beyond the daily inspection requirement. You see the fuel lines, the mags, line of exhaust, the carb heat valve – all the things that you should really learn in a classroom-styled environment. After refamiliarising myself, I immediately felt better equipped to manage in-flight diagnoses if something wasn’t sounding or feeling right.

One of the alternator checks is to put a spanner next to it and feel the magnetism – it should even hold a smaller spanner. This one held absolutely nothing, not even a washer. I then tested it with the multimeter. Positive on the terminal and the negative lead touching the alternator housing. Nothing, which isn’t a good sign. I was able to get a voltage reading everywhere but the alternator, which likely meant I’d isolated the problem.

In discussion with the LAME, Nicholas and I uninstalled the alternator and sent it off to Moorabbin to be checked. Diagnosis? It was absolutely fried and couldn’t be fixed. In came the fresh kit – they’re sold as though you’re doing a full build, so every bolt and clip was supplied (except for the lock wiring, which the LAME completed). The alternator belt was fine and is reviewed ‘on condition’, so we kept it as a spare. We fitted the new alternator, fired it up and all voltage readings returned to normal. Then it was off to the LAME to review and sign off.

Although I generally knew how an alternator worked and the signs of losing them, all of this was a pretty big learning curve for me. Uninstalling, reinstalling and testing a battery. The same with the alternator. Actually getting the multi-meter out and figuring out how to use it. Actually, pressing every button on the Dynon EFIS to find all the options and settings – I was learning the whole way through. Between this, Nicholas was pointing out all the specifics of the engine that he knew (he was also learning, but he’s seen a thing or two).

Our first flight with the new alternator was to outback NSW (and holy moly is it green at the moment!). As we tied the aircraft down, Nick said ‘I’m actually feeling a little bit proud about how we diagnosed that one’. It was actually a bit fun, figuring things out and then checking our facts with the LAME. For two blokes that mostly fly for fun, it felt like a nice little achievement.