A DEEP DIVE INTO AIRCRAFT MATERIALS

We’ve come a long way from spruce frames and canvas coverings. Today, you can find aircraft constructed from a wide variety of materials, including aluminium, titanium-based alloys and various composites. You may have heard the term “composite” thrown around when talking about airframe construction, but what does it actually mean?

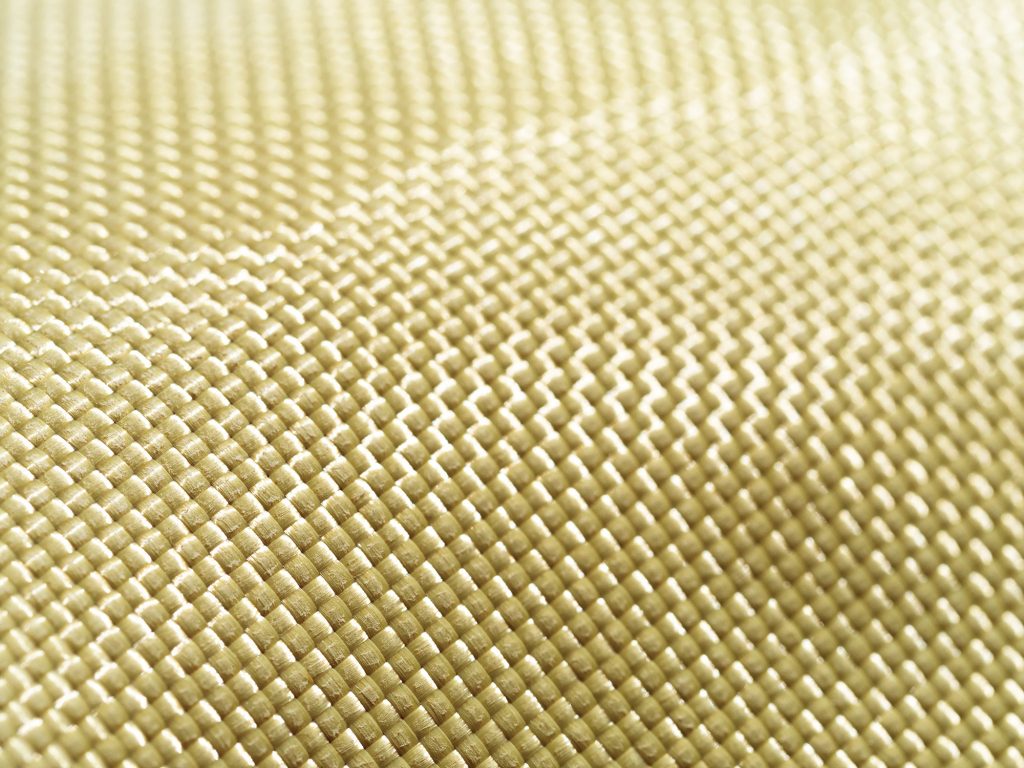

In the simplest terms, a “composite” material is any material that is produced by merging two or more individual materials. Composite materials are engineered to blend the positive properties that multiple materials may have, creating a product that is of greater benefit than either material alone. Oftentimes, this process is used to create materials with high tensile strength, that are also lightweight. Composites are used across a wide number of industries. You’re probably familiar with a number of everyday composites, like plywood and concrete, that have helped us build stronger, more efficient products and structures for centuries. In terms of aircraft design, there are a number of composites that are often used throughout the industry. Some of the most common materials include fibreglass, carbon fibre reinforced polymers (CFRPs) and Kevlar composites. Let’s take a look at each of these and find out what our flying machines are really made of.

Fibreglass is one of the most-commonly found composite materials in aircraft manufacturing, although it has largely been superseded by other materials. Fibreglass is constructed from a plastic matrix, usually epoxy or polyester resin, that has been reinforced with glass fibres. Commercially available since the 1930s, fibreglass is known for its strength, flexibility and its ability to be moulded into complex shapes. This made fibreglass an attractive choice for any would-be aircraft designer, along with a wide variety of other uses. As a result, you’ll find many gliders and light aircraft from the 1960s to the 1980s using fibreglass composites in their designs.

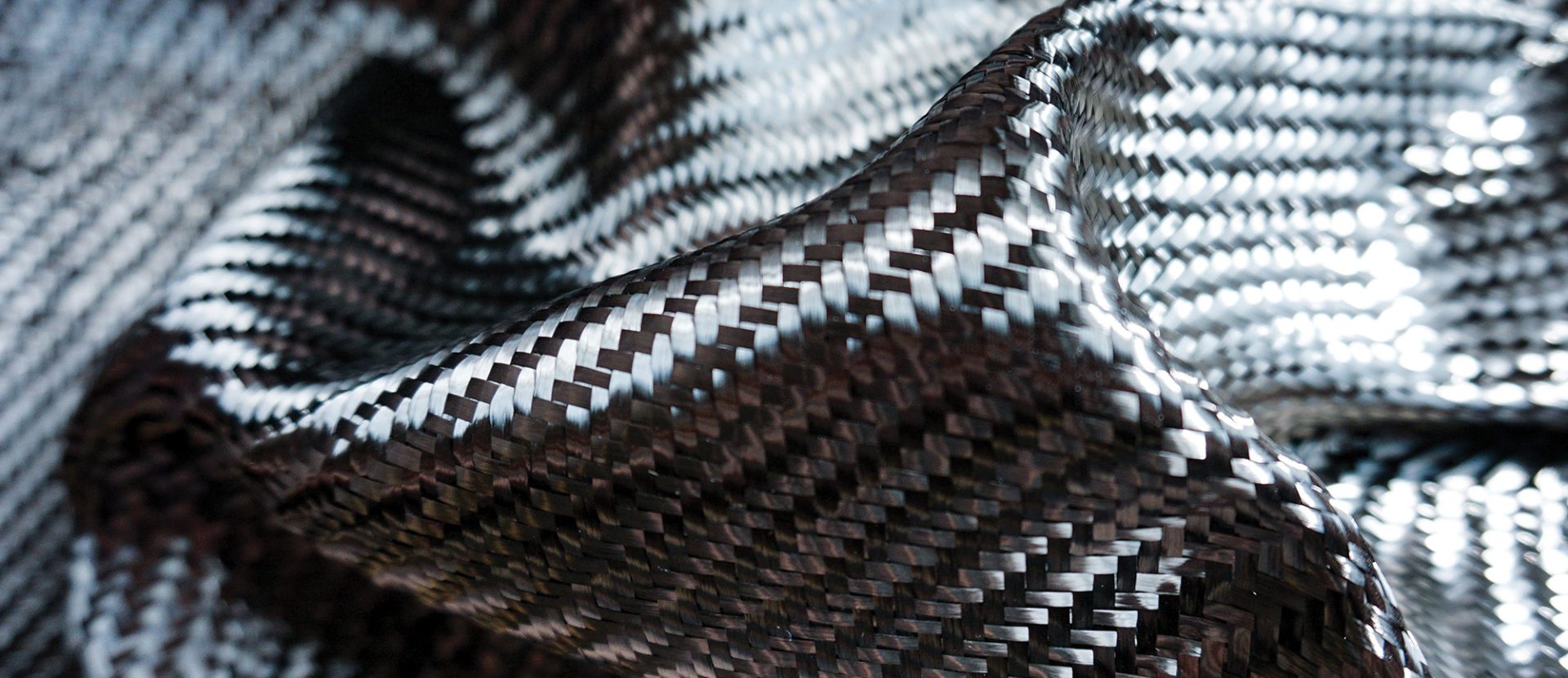

Now, for those of you out there sweating that your aircraft is built from the same material as a circuit board; don’t fret. There is a specific type of fibreglass used for aircraft construction, known as “S-Glass”. It’s an epoxy-based composite, with the highestrated tensile strength of any fibreglass type. The prominence of fibreglass in the aviation industry began to fade from the 1980s onward, thanks in large part to the emergence of a new composite; carbon fibre reinforced polymers (CFRPs). Commonly referred to simply as “carbon fibre”, CFRPs are made by combining carbon fibres with a polymer matrix – usually epoxy.

CFRPs have a higher strength-to-weight ratio than fibreglass, offering improvements in durability and overall efficiency in aircraft design. As the technology required for large-scale production of CFRPs matured in the late 80s and early 90s, CFRPs became widespread in the aerospace industry. Light aircraft began adopting the composite in droves, and even the likes of Boeing and Airbus began making heavy use of CFRPs in their airliners. The Airbus A350, first flown in 2013, is constructed from 52% CFRP. Many popular light aircraft from the late 90s to the present are constructed from CFRPs. Manufacturers such as Tecnam, Jabiru, Pipistrel, Flight Design and TL Ultralight have all made extensive use of carbon fibre composites in their designs.

Recently, aerospace designers have begun making more use of Kevlar-reinforced composites. Kevlar 149, the highest grade of the material available, has a higher impact strength and resistance to heat than carbon fibre. As such, it’s often added to a CFRP composite in components such as the wing leading edge, to provide better protection against bird strikes and other impacts. With manufacturing technologies improving at a rapid rate, the future of composite materials in the aerospace industry is bright. There are several composites and production techniques currently under development that have the capacity to revolutionise light aircraft manufacturing.

One of the greatest challenges we currently face with composites is the difficulty in joining them with metals in complete aircraft builds. There are currently two methods for joining composite components to metal ones. Mechanical fasteners can be used, which require holes to be drilled into parts, damaging load-bearing fibres. Adhesive bonding can also be used, although this often adds considerable weight and can nullify the potential benefit of using composites in the first place. Recent research into the use of thermoplastics has produced exciting results in this area. Unlike epoxy and other polymer matrices, thermoplastics can be welded and thermoformed to fit metal parts perfectly. It’s still early days, but successful, scalable experiments in this field may give rise to lighter, stronger airframes across the aerospace industry.

For recreational pilots, particularly those flying on their own dollar, the efficiency improvements that composite aircraft offer is exciting. It remains to be seen where the next innovation in aircraft materials will be, but it’s clear that designs will continue to evolve into the future.