THE NITTY GRITTY ON STALL WARNING INDICATORS

You might have heard of stall warning devices, but if you have never flown with one in RAAus you are not alone. At present, many light aircraft are simply not fitted with them. Let’s dive in and understand what they are, how they work and how they can help improve safety in aviation.

In many GA Aircraft and just about all commercial planes, there is a small device installed that when the plane is getting close to a stall (around 5 – 10 knots from stalling), they will alert the pilot. Some will have an inbuilt verbal alert, especially aircraft with glass panels. Some commercial planes have what is known as a ‘stick shaker’, which is a device that adds a vibration to the yoke when it is approaching a stall. But most commonly, in lighter aircraft, is the stall horn or electronic equivalent. It varies between devices, but generally as the plane gets closer to stalling either the pitch will change or the stall beeping will become more frequent, not that dissimilar to the sound of a metal detector.

There are three main kinds. The horn, lift detector stall warnings and Angle of Attack (AoA) Sensors. The first of these created, and by far the simplest, is the stall horn. It is just a small opening that sits on the leading edge of the wing, which acts more or less like an umpire’s whistle. As the wing approaches a stall, the location where the air splits around the wing shifts. This ingenious little device takes advantage of the shift in air pressure and direction, triggering the whistle via a tube that comes out of a horn, which amplifies the sound into the cockpit. When fitted, it’s the last thing you’ll hear before touching down on the runway.

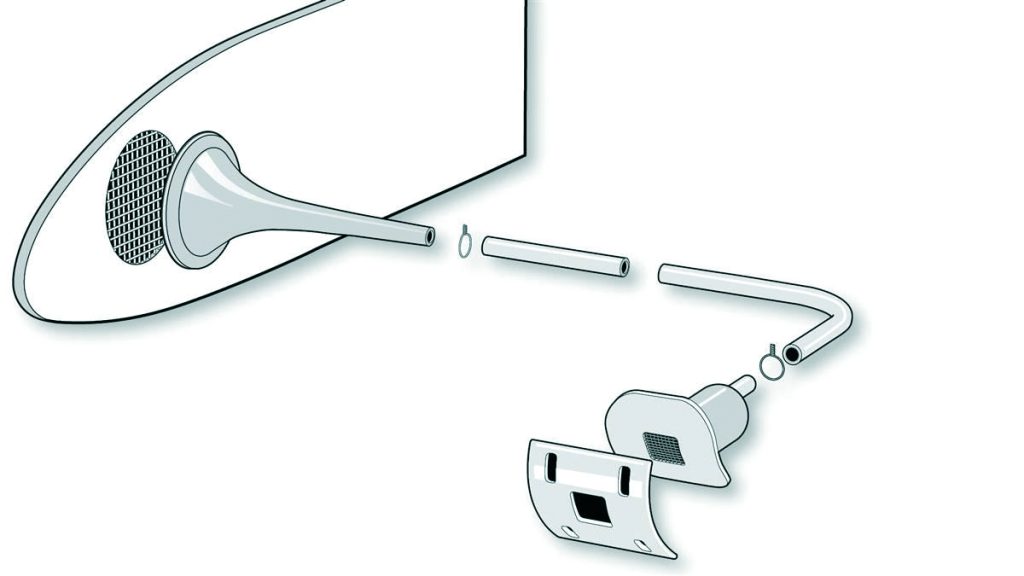

The second type is the lift detector. These devices are slightly different, but the principles that activate them are the same. There are small tabs that stick out of the leading edge of the wing (sometimes slightly below). As the plane approaches a stall, the airflow will the push the tab up from its natural flying position, transmitting a signal to the cockpit via a 12 or 24 volt cable, triggering an electronic horn. As it is electronically controlled, there are additional devices that can be setup to show how close to the stall the pilot is. Some STOL pilots will use this to aid them in their short field landings.

And finally, there are Angle of Attack Sensors. Most of these work by having a windvane attached to the outside of the aircraft. These work by connecting to the plane’s pitot and static pressure sensors, airspeed and other internal sensors. They then combine this information with the plane’s angle of attack, angle of bank, the plane’s inertia and G-force, to accurately calculate the plane’s stall speed. It is worth mentioning that these systems have been around for quite some time, being used by commercial airliners for decades. They weren’t always available to the average recreational pilot, cost-effectively, but this has since changed for the better. Not only have they become more affordable, but there are a lot more options driving innovation.

You may have flown quite some time with no such device and be very familiar with the early warning signs of a stall such as the ‘mushy’ flight controls, but let’s use a hypothetical example to try and illustrate the case:

It has been a while since you have flown, so you head out to the airport to do a few circuits and keep your skills sharp — being the responsible pilot that you are. You’re keeping a watchful eye on two other planes in circuit, calling their positions and intentions. You’re running through your downwind checks, keeping an eye on the sock, making your base call, then slowing your speed as you prepare for final – when a fuzzy radio call comes through, and you can’t make out their position or intention. As you juggle controls and instruments, albeit a little rust-like, you feel the controls need more input before you feel the dreaded drop of a wing.

It’s not a situation unheard of. The unfortunate thing about this story is that it occurs too often in real life. No one wants to stall on final approach. From 2015 and 2020, 60% of RAAus fatal accidents are believed to have occurred due to loss of control events. One of the most dangerous times to enter such an event is the situation described above, as there isn’t a lot of altitude to recover unless it is detected and corrected immediately. When stall warning indicators have existed for so long and can help avoid such incidents, it surprises me that they are not installed more commonly. They’re a tool to assist any pilot in such a situation.

There’s an argument not to have them, due to pilots then relying on them, or the cost. I understand that to a degree, but I don’t drive my car more carelessly just because of my airbags and seatbelt. The cost to install when ordering or building a plane is, quite frankly, peanuts when compared to other instrumentation — given the added safety benefit. I find it hard to argue against them.

So, if you are looking at building a kit, ordering a new aircraft or just doing some modifications to your current plane, take a look into stall warning indicators and what they can offer. And, if you are looking to retrofit, there are now many other options on the market that don’t require wing modifications bringing the barrier to within reach of RAAus pilots.

Addition of a stall warning may be classified as a major modification. Contact RAAus Tech prior to modification to ensure compliance.