1 JANUARY – 30 JUNE 2022

- 6 Aircraft Destroyed

- 38 Aircraft Damaged

- 11 Injuries

- 38 Flight Training Occurrences

- 52 Private Operations Occurrences

ENGINE FAILURE OR MALFUNCTION OCCURRENCES

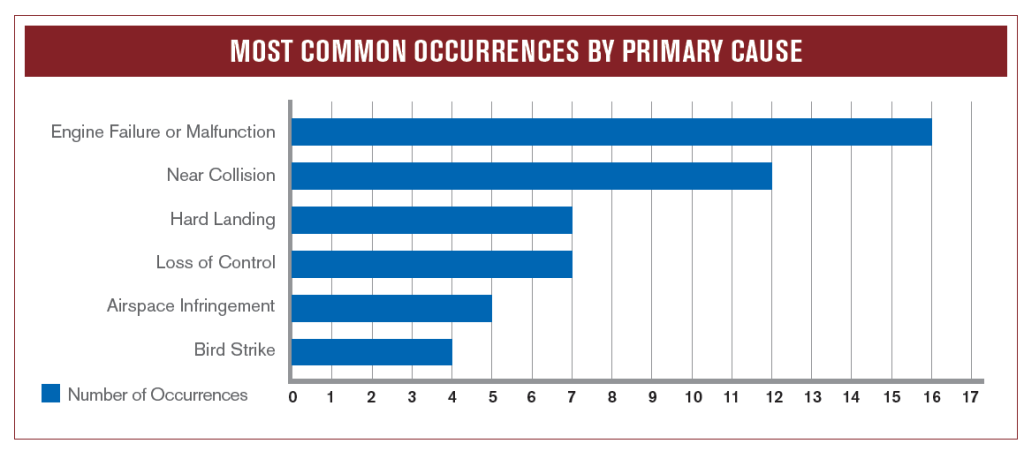

RAAus had 16 engine failure occurrences reported during the first half of 2022. Of these 16 occurrences, 9 were in Rotax engines, with 7 in Jabiru engines. These events occurred due to a range of different contributing factors including fuel, ignition, and mechanical failure. Several of these occurrences may have been prevented through thorough maintenance practices with at least two occurrences which may have been identified through more thorough preflight inspection.

NEAR COLLISION

Near collision occurrences continue to rate highly in RAAus occurrence data with all occurrences taking place in the vicinity of an aerodrome, primarily within the circuit. Within the first half of 2022, RAAus has seen an increase in the number of occurrences for which conflicting circuit direction has been a contributing factor, in particular a number of occurrences were reported with aircraft electing to take-off in conflict with established traffic on the opposite runway. Other contributing factors include poor radio communications and non-standard circuit procedures.

HARD LANDING

RAAus had seven hard landing occurrences reported within the first half of 2022, with all occurrences resulting in damage to the aircraft. Of these occurrences, 5 resulted in undercarriage failure and propeller strike and 5 occurred following a bounce on landing. Three occurrences involved a solo student and many of these occurrences may have been avoided if the pilot elected to conduct a go-around. Pilots should always be prepared to conduct a go-around in the event of a bounce during landing and particular attention should be paid to daily and maintenance inspections of undercarriage components of RAAus aircraft. Following a hard landing, a hard landing inspection should be conducted by an appropriately qualified maintainer even if no visible damage exists – This may assist in preventing undercarriage failure during future flight.

LOSS OF CONTROL

Loss of control events continue to be the highest cause of aircraft damage and injury within RAAus operations. Of the 7 loss of control events reported to RAAus within the first half of 2022, 3 occurred during landing, 2 during take-off and 2 during a touch and go. The most common contributing factor reported to RAAus was wind conditions, three occurrences reporting crosswind conditions and two occurrences reporting tailwind conditions. Two occurrences took place during dual flight training operations. Pilots are reminded of the importance of reviewing weather forecasts and reassessing conditions prior to and during flight. Several of these occurrences may have been avoided by electing to land on the most into wind runway rather than accepting a crosswind or tailwind component.

OCCURRENCE SUMMARIES

Occurrence Classification: Loss of Control

Operation type: Flight Training — Dual

Injuries: Minor

Damage: Destroyed

An instructor and student were conducting dual flight training. During a touch and go the student lost directional control, first to the left then to the right. The instructor took control of the aircraft, however was unable to recover directional control. Power was reduced power to idle and the aircraft exited the right of the runway, cartwheeled once and came to a halt on its roof, upside down. The instructor and student were uninjured however the aircraft was destroyed.

Occurrence Classification: Aircraft Preparation

Operation type: Private

Injuries: Nil

Damage: Nil

After carrying out minor maintenance on the aircraft, the pilot re-attached nose cowlings and prepared the aircraft for flight. The pilot conducted a normal take-off and the climb attitude was set. The pilot noticed the airspeed was very low and fluctuating and identified they hadn’t removed the pitot cover. The pilot continued to carry out a circuit with GPS ground speed used as backup. The aircraft landed without further incident. The aircraft landing gear was inspected for a possible high-speed touch down and the pitot tube inspected. The pilot identified that the error probably resulted from mixing maintenance actions with flight actions and advised they would separate these actions in the future to ensure all pre-flight actions were completed as normal.

Occurrence Classification: Near Miss

Operation type: Flight Training — Dual

Injuries: Nil

Damage: Nil

There were three aircraft established in the circuit, conducting touch and goes on runway 25. A VH-registered aircraft entered the active runway and prepared to take-off in the opposite direction of the circuit on runway 07 when the pilot was contacted via radio advising of existing traffic. The pilot of the aircraft on the ground stated “the wind had changed and that the preferred runway was 07”. The pilot was then again contacted by another pilot downwind that three aircraft were already operating and established in the circuit for runway 25.

The pilot ignored information received and commenced take-off on 07 with another aircraft on final for runway 25. As a result, the pilot had to make an evasive turn to the left to avoid the aircraft on final. The aircraft on final commenced an orbit to avoid opposite direction traffic.

As this matter involves the actions of a VH-registered aircraft the occurrence was forwarded to CASA for review in order to address safety concerns relating to the actions of the pilot involved. RAAus received confirmation that this occurrence will be reviewed by the CASA surveillance team.

Occurrence Classification: Defect Report

Prior to flight as the pilot was securing their harness a tearing sound was heard and the shoulder harness was observed to detach from the aircraft. Upon further inspection it was identified that the sewn section of the harness behind the seat had come loose causing the harness to separate.

Due to the safety-critical nature of this finding, RAAus initiated immediate contact with the aircraft distributor who made further contact with the manufacturer. RAAus issued an advisory notice to all owners of the aircraft type recommending inspection of the seat belt harness before further flight. The manufacturer then released a safety directive to advise aircraft owners.

Reporting of defects is a mandatory requirement and assists in identification and resolution of hazards which may occur for a particular aircraft. Defect reports can be submitted at reporting.raaus.com.au

Occurrence Classification: Carbon Monoxide

Operation type: Flight Training — Dual

Injuries: Minor

Damage: Nil

During flight carbon monoxide (CO) was indicated in the cockpit. The aircraft was fitted with a card CO detector on the instrument panel which was noticed to be discoloured. One occupant experienced symptoms raaus.com.au/shopconsistent with elevated levels of CO exposure. There was no previous history of CO ingress into the cockpit. Further inspection revealed that a missing rear fairing screw was allowing carbon monoxide to enter the cockpit. The screw was replaced and issue resolved. Pilots and aircraft owners are reminded that the presence of carbon monoxide within the cockpit may result in pilot/passenger incapacitation. Fitment of electronic carbon monoxide detectors are strongly recommended and available from the RAAus shop. More information on the dangers of carbon monoxide are available from the ATSB and CASA websites.